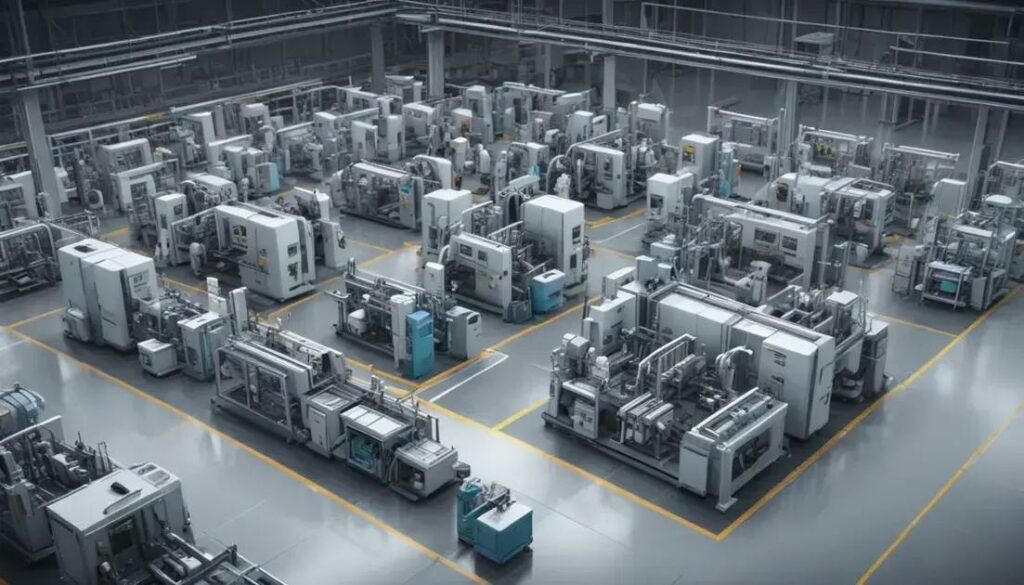

Manufacturing continues to play a vital role in driving the global economy, yet it faces significant hurdles that can affect its efficiency and profitability. From supply chain disruptions to rising operational costs, manufacturers need to adapt quickly. Curious about how others are overcoming these challenges? Read on!

The manufacturing industry faces several key challenges that affect its efficiency and growth. One big issue is supply chain disruptions. These can happen for many reasons, like natural disasters or shipping delays. When materials don’t arrive on time, production slows down, leading to missed deadlines.

Rising Costs

Another challenge is rising operational costs. Costs for raw materials and labor are going up. This can squeeze profit margins. Companies must find ways to cut costs without sacrificing quality. One method is by investing in better technology, which can make processes more efficient.

Workforce Issues

Finding skilled workers is also tough. Many companies struggle to find employees who have the right skills. This skills gap can slow down production. Training staff is essential, but it takes time and resources.

Regulatory Pressures

Manufacturers also deal with strict regulations. These rules can change often and may require costly updates in production methods. Staying compliant is crucial but can be a burden.

Lastly, keeping up with technology is vital. New technologies like automation and AI can improve productivity. However, adopting these can be complex and require a significant investment.

By addressing these challenges head-on, manufacturers can improve their operations and remain competitive in a fast-changing market.